In a world first, the Royal Mint in the UK has announced a partnership with Canadian startup Excir to retrieve and recycle gold and other precious metals safely from discarded smartphones and laptops.

Excir’s pioneering technology extracts 99 per cent of gold and other precious metals from the circuit boards of electronic devices at room temperature rather than at high temperatures in smelters.

The circuit boards are removed from electronic devices and mixed with a patented chemical formula that dissolves the gold into liquid. The gold can then be extracted from the liquid via precipitation and turned into ingots, which the Royal Mint can use to create new products.

In the pilot project, Excir’s technology will be scaled from the laboratory to a commercial setting. The Royal Mint hopes to recover palladium, silver and copper using the same process.

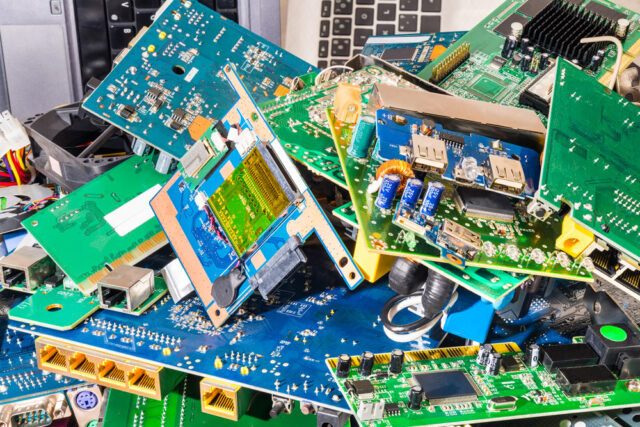

Mountains of e-waste

Electronic waste is a huge global problem. According to the WEEE Forum (the International Association of Electronic Waste Producer Responsibility Organisations), waste electrical and electronic equipment (WEEE) will total 57.4 million tonnes in 2021. By 2030, the WEEE Forum forecasts e-waste to total 74.6 million tonnes. Less than 20 per cent of electronic waste is currently recycled.

According to the Royal Society of Chemistry, UK homes contain up to 40 million unused phones. These gadgets contain at least 30 naturally occurring elements, six of which – gallium, arsenic, silver, indium, yttrium and tantalum – are set to run out within a century.

Recovering precious metals and other elements from e-waste is known as “urban mining”. Ruediger Kuehr, head of the United Nations Institute for Training and Research Office in Bonn, Germany, and director of the Sustainable Cycles Programme (SCYCLE) at the United Nations University, says a tonne of discarded mobile phones contains more gold than a tonne of gold ore.

“Embedded in a million cell phones, for example, are 24 kilograms of gold, 16,000 kilograms of copper, 350 kilograms of silver, and 14 kilograms of palladium — resources that could be recovered and returned to the production cycle,” Kuehr says. “And if we fail to recycle these materials, new supplies need to be mined, harming the environment.”

Contributing to a circular economy

Founded in 886, the Royal Mint is one of the UK’s oldest organisations. Its partnership with Excir represents a new chapter in the organisation’s long history and an important milestone on the path to sustainability.

“It provides us the opportunity to make a genuine impact on one of the world’s greatest environmental challenges while helping to secure our future as a leader in high quality, sustainable precious metals,” says Royal Mint CEO Anne Jessopp.

“The potential of this technology is huge – reducing the impact of electronic waste, preserving precious commodities and forging new skills which help drive a circular economy.”