Thanks to an ever-changing industry landscape and the introduction of electric vehicles, a fleet manager’s role can be complex and challenging. Here we talk to IPWEA member Peter Porch about his main duties and responsibilities.

The fleet management industry boasts a diverse range of roles – and the people that fill them each has a unique story to tell of their journey into the sector.

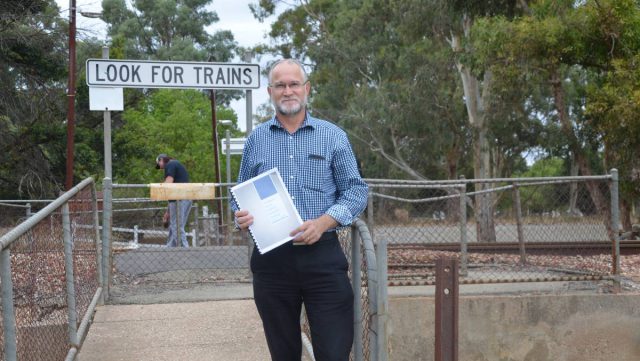

Here we talk to Peter Porch, Manager Operational Services, Northern Areas Council, South Australia, about his background, a fleet manager’s duties and responsibilities, and the importance of sharing information.

How did you get started in fleet and plant, and what was your first job in the industry?

Peter Porch: My first exposure to plant and fleet management was in private industry, where plant and equipment management for a moderate-size civil and building construction company formed a component of my substantive role.

Tell us about the fleet manager’s role and the kind of fleet and plant you manage.

PP: I’m Manager of Operational Services at Northern Areas Council in regional SA. The organisation is not large enough to have a dedicated plant manager, so the activity forms a part of my substantive role. I have two great mechanics, one of whom coordinates the workshop activities, and I have another coordinator who is developing in plant management as a component of a technical role. We have a $1 million plant-replacement budget annually with internal hire around $1.65 million annually. Amongst our fleet are six graders, three prime movers and four water carts. We also raise around 130,000 tonnes of our own rubble with our own bulldozer and crusher.

What’s the favourite part of your job? How do you improve fleet management?

PP: I enjoy finding efficiencies and developing useful data for analysing results. We introduced a 30-metre road train to our fleet this year, with some ingenious work by the team, delivering significant savings to our re-sheeting program.

What are some of the fleet-management industry challenges?

PP: Some of the largest challenges are sometimes the smallest items. We have been following up options to provide a workable towing frame for utes behind our maintenance graders for four years. Getting a compliance plated accessory like this to facilitate efficiencies in operations is often a hard slog. The ever-tightening compliance requirements will continue to challenge our ingenuity into the future.

How do you think the fleet department can make sure it has buy-in and support from the rest of the organisation?

PP: Information sharing is always a key to achieving buy-in. The fleet we procure and maintain is not for us the purchaser – it’s for others to use. So involving the end users and the other number-crunchers in finance is an important aspect of the fleet manager’s role.